Ink scraper control in offset printing is a complex process of ink transfer, including ink, plate and paper. In gravure printing, ink scraper is a mechanical operation, relatively simple, but it has its own unique. Ink scraper must have wear resistance and high efficiency, in order to ensure the printing of high quality, and it must be suitable for the modern gravure printing of durable and high-speed needs. Ink scraper is a thin sheet used to scrape excess ink off the surface of the drum on the printing press. It is divided into metal and non-metal. Ink scraper in each printing process, the removal of unpatterned areas of ink is a key point.

Application: Printing varieties

Gravure, flexo printing, generally according to the following printing categories to choose the required blade, but the error of the required blade is not more than +5um. 50um: Mainly used for ordinary packaging printing: paperboard and decoration printing, etc.

The printing substrate

Paper, plastic film, aluminum foil, etc., need 75um ink scraper, mainly used for gravure printing film, aluminum foil, etc. Scraping ink.

Ink features

Soluble, water-based, coating materials, 100 um: mainly used for flexible printing, coating and cots, and 125 um: mainly used for flexible printing: ceramic roller, etc.

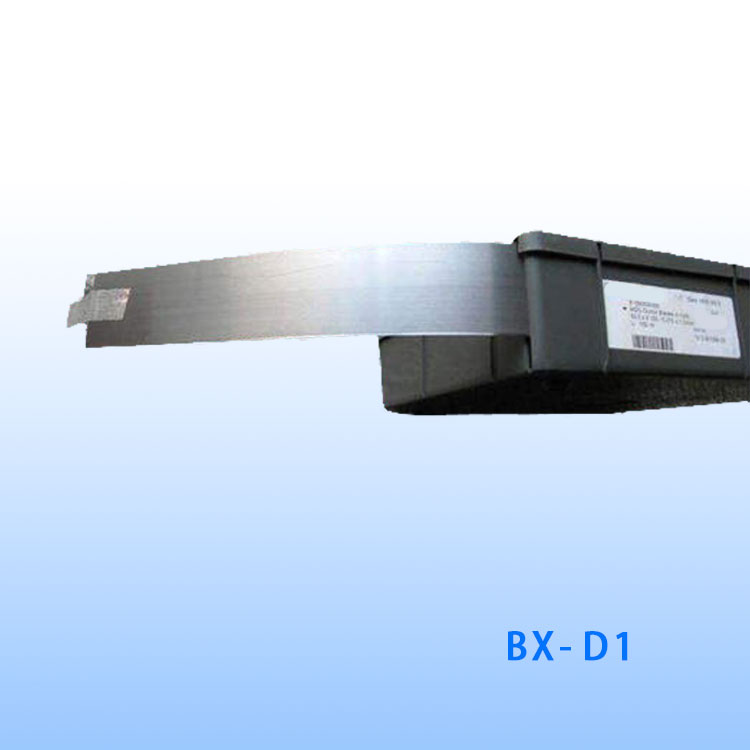

Material: According to the quality of scraper base material, it can be divided into the following scraper:

1. Carbon steel blade

2. Plastic scraper

3. Coating scraper

4. Stainless steel scraper

Ink scraper material requirements with high quality, clean, no impurities, wear - resistant.